Researchers from the University of Illinois at Urbana Champaign have devised a new method for fabricating brighter and more efficient green LEDs. Using a standard semiconductor growth method, the researchers have grown gallium nitride (GaN) cubic crystals on a silicon substrate. The cubic GaN-on-Si crystals can produce powerful green light.

The two typical types of GaN crystal structures are hexagonal and cubic. Hexagonal GaN, the more conventional form, is thermodynamically stable. However, the researchers point out that hexagonal GaN is prone to polarization, in which an internal electric field separates the positively charged holes from negatively charged electrons and prevents them from combining. Preventing the electrons and holes from combining diminishes the light output efficiency.

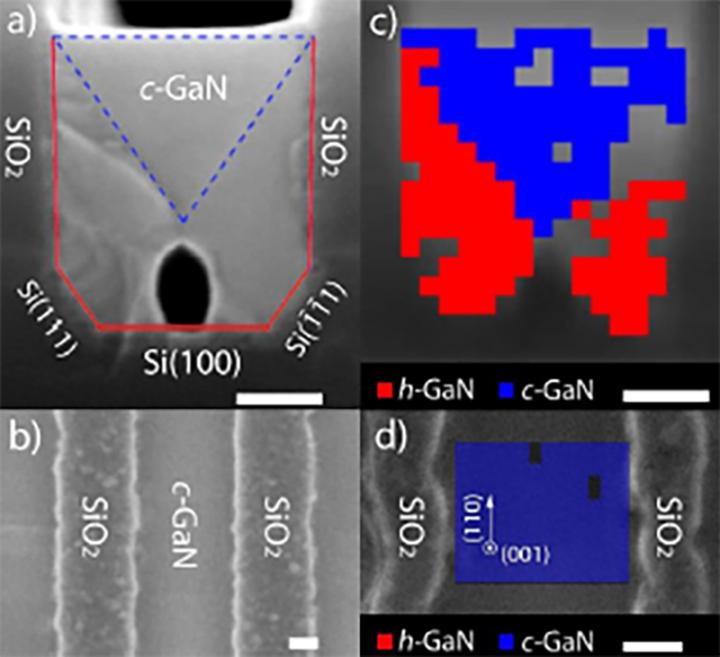

A new process of cubic phase synthesis: Hexagonal-to-cubic phase transformation. The scale bars show 100 nm in all images. (a) Cross sectional and (b) Top-view SEM images of cubic GaN grown on U-grooved Si(100). (c) Cross sectional and (d) Top-view EBSD images of cubic GaN grown on U-grooved Si(100), showing cubic GaN in blue, and hexagonal GaN in red. Images courtesy of University of Illinois

The researchers assert that previously, the only way to produce cubic GaN was to grow it with molecular beam epitaxy, a very expensive and slow crystal growth method compared to the metal-organic chemical vapor deposition (MOCVD) method that Bayram used. Bayram and Richard Liu, his graduate student, first used lithography and isotropic etching to create a U-shaped groove on Si. This non-conducting layer serves as a boundary which shapes the hexagonal crystal material into cubic form.

“Our cubic GaN does not have an internal electric field that separates the charge carriers-the holes and electrons,” explained Liu. “So, they can overlap and when that happens, the electrons and holes combine faster to produce light.”

“This work is very revolutionary as it paves the way for novel green wavelength emitters that can target advanced solid-state lighting on a scalable CMOS-silicon platform by exploiting the new material, cubic gallium nitride,” said Can Bayram, an assistant professor of electrical and computer engineering at Illinois.

Bayram and Liu speculate that their cubic GaN fabrication method may lead to LEDs free from the “droop” that has plagued the LED performance. “Droop” causes the light emission efficiency of green, blue, or ultraviolet LEDs to decline as more current is injected.

“Our work suggests polarization plays an important role in the droop, pushing the electrons and holes away from each other, particularly under low-injection current densities,” said Liu.

The researchers published their findings in Applied Physics Letters.

More efficient Green emitting LEDs can improve solid state lighting in LED lights that use a combination of red blue and green LEDs to produce white light. Other potential applications include ultra-parallel LED connectivity using phosphor-free green LEDs, underwater communications, and biotechnology such as migraine treatment and optogenetics. The researchers note that Bayram’s cubic GaN could also go into ultra-violet LEDs for water disinfection and power electronic devices.